Products

- Printed rollstock

- High-barrier flexible packaging

- Matte/gloss flexible packaging

- Compostable flexible packaging

- Recyclable flexible packaging

- Stick pack film laminations

- Lidding films

- Peel and reseal rollstock

- Shrink bands

- HFFS and VFFS rollstock

- Inno-Lok® pre-zippered rollstock

- Laser die-cut window rollstock

- Paper flexible packaging

- High burst strength flexible packaging

- Child-resistant flexible packaging

- Premade pouches

- Roll-fed labels

- Shrink sleeves

- Stretch sleeves

- Cold-seal packaging

- Thermoformed food trays

- Functional bags & pouches

Poly bags

From standard poly bags to a more customized package, C-P Flexible Packaging provides quality printed bags for your specific application in a variety of markets such as food, industrial, and medical.

Our expertise and state-of-the-art polyethylene bag converting lines support the demand for a wide variety of bag types and features:

Our expertise and state-of-the-art polyethylene bag converting lines support the demand for a wide variety of bag types and features:

- With or without recloseable options

- Custom-printed HD graphics

- Zipper/tape closures

- Pressure sensitive label (PSL) in-line adhesion

Products and capabilities

Recognized as a leader in custom design and manufacture of flexible plastic packages, our extensive materials capabilities and application expertise enables us to engineer poly bags to meet your equipment and product requirements.

We provide quality custom printed bags for your product needs with quick turnaround times. We can provide everything from standard poly bags to a more customized package.

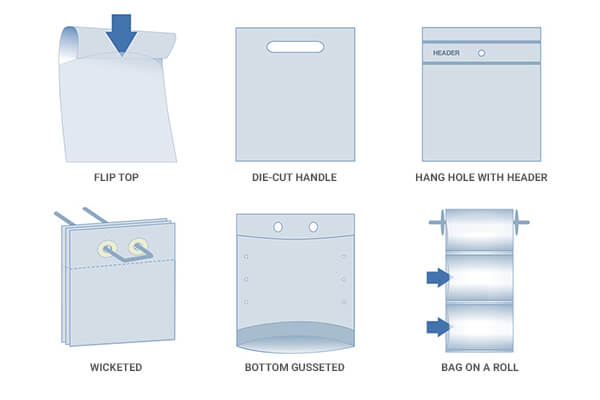

Poly bag formats and features

Flip top bags

Flip top bags- Bags with die-cut handles

- Hang hole with header seal bags

- Wicketed bags

- Bottom gusseted bags

- Bag on a roll

- Pop-open bag on a roll

- Tamper-evident bags

- Recloseable zipper bags

- Mailer bags

- Dual-pocketed bags

- Bags with tear-away coupons

- Security bags

- Large-format bags

Crimp bottom bags

Crimp bottom pre-made bags provide the barrier and sealing necessary to give products a better shelf-life. This is especially helpful for products like:

- Pasta

- Popcorn

- Baked goods

C-P specializes in designing and manufacturing customized mono layer polyethylene (PE) rollstock primarily for retail industries including home care, food & beverage, and more.

Our roll stock product is planned and produced to meet your specifications with complete “one point of contact” service and efficiency.

Roll stock packaging may include:

- Centerfold and J-sheeting

- Pinwheel perforations and microperforations (micro-perf)

- Flood coated for a full-bleed print

- Surface and reverse print

- State-of-the-art poly bag converting lines

- Increased efficiency

- High-production rate

- Increased quality

- Quick changeovers

- Enhanced automation

- Advanced workflow and data collection

- Central impression flexographic printing presses

- Better registration

- Up to 10 colors

- Wide web priority

- Bag on a roll machines

- Bag making machines

- Wicketed bag machines

C-P Flexible Packaging provides custom graphic designing expertise. We can design custom flexible packaging using your company identification or adjust your artwork to work more efficiently.

Accelerate your success with our expert graphics group

Each member of our graphics group has been hand-picked for their in-demand skills. We believe technical skills are extremely important, but the passion and ingenuity are the foundation of our success. At C-P, you’ll find a “make it happen” approach to every project. These graphic specialists have a genuine desire to grow and contribute. It’s this kind of inventive culture that sets us apart.

Key services

- Packaging / printing consultation – experience to make flexography work for you.

- Graphic design

- Artwork finalization

Whether you are a seasoned expert in the flexible packaging industry or a new business developing packaging for the first time, our quality assurance team will assist you in deciding on the ideal package for your product. Our analysis lab provides a variety of valuable resources for any stage of your packaging development process. Our goal is to put your mind at ease, assuring you that the packaging decisions you make will be cost-effective for your company and exceeding industry standards for your customers. Our team can test plastic film for many different aspects of production, including:

Color measurement (LAB value)

Used to determine a specification for an acceptable color range instead of just what looks good “by eye”. This reduces color variation from package to package.

Color matching

C-P can read a color off a film sample to match an exact color or determine the closest PMS color in our printing process.

Scuff resistance of ink

Determines how durable the ink needs to be to survive transportation and shelving

Ink adhesion

Ensures ink will not peel or pick off plastic film.

Opacity levels

Measures the amount of white or any other color ink to determine acceptable print appearance.

Varnish quality

Calculates coating weight of the varnish to establish minimum amounts for a high-quality product.

Accurate gauge testing

Confirms the thickness of a film sample to guarantee appropriate film strength.

Oxygen barrier capability

Measures the amount of oxygen allowed to go through the film, which helps determine the shelf life of the product being packaged.

Moisture barrier capability

Measures the amount of water vapor allowed to go through the film, which helps determine the shelf life of the product being packaged.

Percentage of haze or clarity of film

Measures clarity of film, which is important when show casing product inside your package.

Tensile properties of film

Measures the strength or the elasticity of film before it breaks.

Compositional analysis

Denotes the exact materials a film sample is made of (Polyethylene, Polypropylene, Polyester, etc.).

Pouch configuration

Create hand sample or mock-up of pouch for review.

Seal strength

Measure the strength of a seal or how difficult a package is to open.

Coefficient of friction (COF)

Assesses the amount of friction in the film. This determines how much “slip” your package will have when running through your packaging lines as well as help establish the raw material properties needed for your loading machines.

Perforation strength

Evaluates tear-off strength (force needed to peel a perforation apart). This is the ideal measurement for loading machines at your packaging sites.

We provide just-in time delivery, EDI order handling, inventory management & continuous replacement, materials traceability & other lean supply chain services. We can bring more convenience, speed and efficiency to your ordering and production processes while reducing inventory costs.

Our lean supplier services include:

VMI (Vendor Managed Inventory) – To maintain a customer’s inventory at agreed upon levels. VMI allows C-P Flexible Packaging to continuously monitor your inventory.

EDI (Electronic Data Interchange) – Transfer your orders, usage, inventory levels and other data fast, automatically and error free using EDI, Electronic Data Interchange.

CRP (Continuous Replenishment Program) – We can automatically ensure on-time replenishment of your packaging material inventories when we are couple to your operations with using EDI to the electronically transfer of data.

FTP (File Transfer Protocol) – We can also link with your scheduling and production management systems using FTP.

Certifications – C-P complies with the following standards to further ensure quality and customer satisfaction: AIB (American Institute of Baking)

Markets and technology

C-P’s poly bag department supports growth for food, health care, and industrial applications through traditional retail distribution as well as the rapidly growing e-commerce channels.

Our state-of-the-art poly bag converting lines feature enhanced automation, quick changeovers, best-in-class efficiencies, workflow, quality, and data collection.

- Private label

- Packaged goods

- Frozen – ravioli

- Produce

- Snack

- Bakery

- Pet Food

- Consumer products

- Paper plates

- Tissue and towel products

- Household cleaning products

- Cosmetic

- Lawn & Garden

- Fertilizer

- Medical

- Textiles

- Chemical

- Contract manufacturing

- Mailing & security

- Commercial printing

- Plastics

Innovation and sustainability

C-P continues to strategically expand its product portfolio and will invest in new technologies that provide innovative solutions for our customers and best-in-class quality.

Demand for our high-performance polyethylene bags continue to increase due to efforts to lightweight packaging as part of corporate sustainability initiatives.

Developing new packaging structures that can be recycled or that incorporate recycled content will remain key areas of focus as it pertains to our commitment to sustainability.

We believe in responsible industry leadership, creating profitable growth in harmony with environmental sustainability and good corporate citizenship. We intend to fulfill this responsibility by providing the best possible packaging solutions for our customers; as well as addressing the carbon footprint with responsible manufacturing processes.

Waste from day-to-day operations is taken to a local Waste-To-Energy (WTE) plant, where our waste is converted into fuel to generate electricity.

We will continue to explore and expand our knowledge of sustainable products and procedures in the following three elements:

- Products

- Manufacturing

- Supportive activities to the business

Energy recovery

- Heat from the manufacturing process is recovered to provide heat to the entire facility.

- Outside winter air is used to replace process chilling power costs.

Recycling

Plastic, cardboard and paper products are recycled through the corporation.

Energy savings

- Facility lighting has been upgraded to high efficiency.

- We have been accepted into the New York Power Authority’s program (NYPA) for the use of water power from Niagara Falls.

Packaging & material design savings

- Customer orders are scrutinized for size and gauge to save on packaging.

- In-plant F.D.A. approved recycled and post consumer recycled films are offered to our customers.

- Multi-layer co-extrusions can conserve material and cost.

Living the sustainability philosophy

A sustainability committee has been formed at C-P to work in all departments to help reduce, reuse and recycle. We have extended this process to the team members by showing them how to be sustainable at home.

Let's talk flexible packaging.

Ask us your packaging questions, and we’ll see how we can help you overcome your next packaging challenge.

Sustainable Packaging

Learn more about our sustainable packaging options including: recyclable, PCR, compostable, and biopolymer usage

GreenStream Products